Product classification

Classification of heavy equipment

Reducer classification

Classification of heavy equipment

O-SEPA high performance powder separator

Classification:

Powder Separation and Dust Removal Equipment

Key words:

Product Description

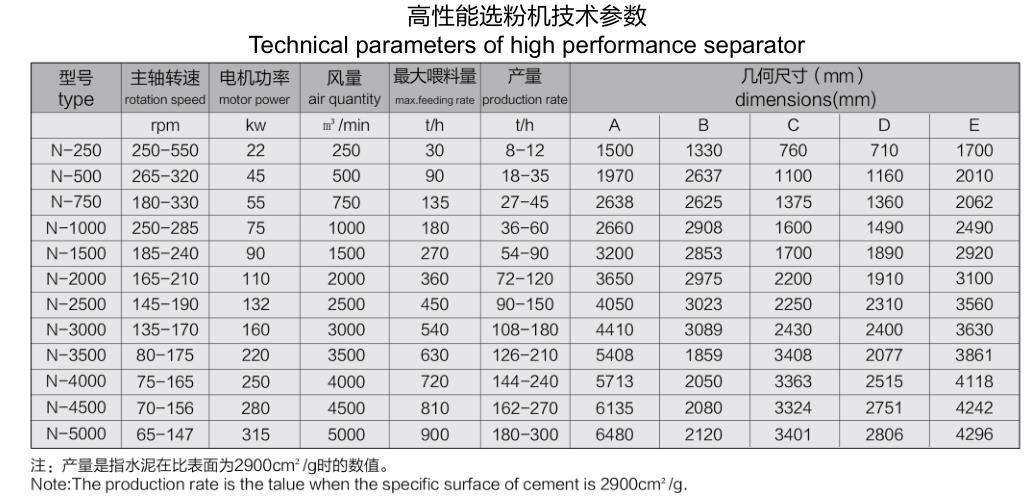

O-SEPA high-performance powder separator is the fourth generation of high-efficiency powder separator utilizing the horizontal eddy current principle for classification, it is the powder classifying equipment which is improved and perfected by our company on the basis of introducing foreign technology and combining with the specific production practice of our country, it is widely used in the classifying of powder or other industrial equivalent materials, it has the advantages of high yield and low consumption, large processing capacity, simple operation and maintenance, and so on.

The main advantages are as follows.

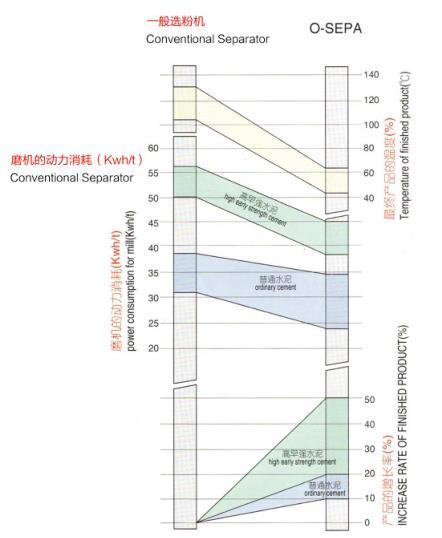

(a) Increase production; (b) Reduce energy consumption; (c) Improve quality and reduce cost; (d) Simple operation and easy adjustment of fineness; (e) Low wear and tear, simple maintenance; (f) Large capacity of handling powder; (g) High efficiency of powder separation.

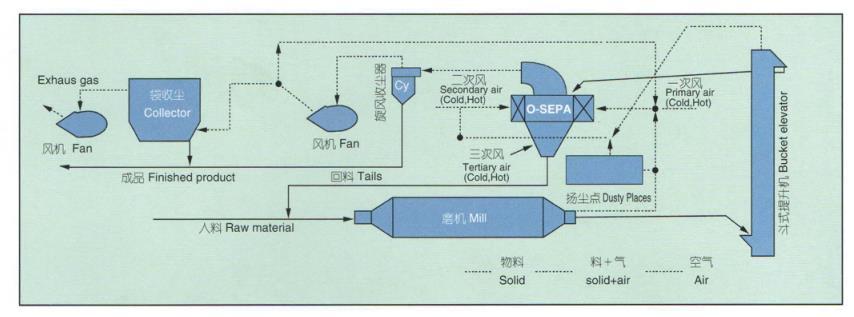

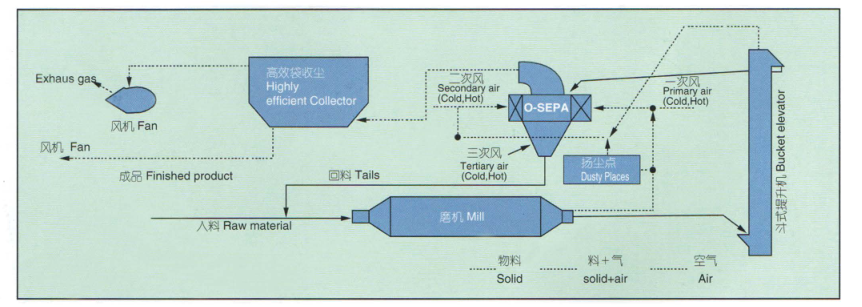

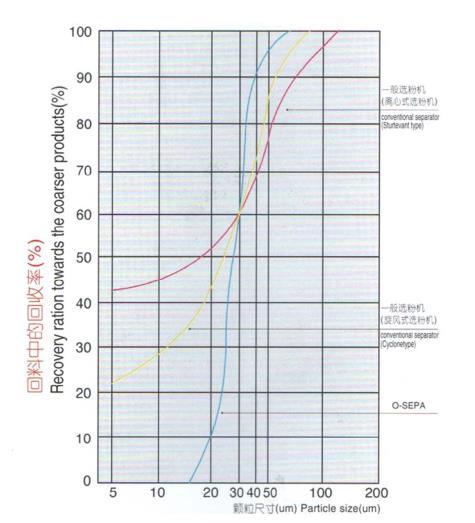

Comparison of curveO-SEPA and general separator : The following figure shows the comparison data between general separator and O-SEPA in the production of common cement.

Scope of application of O-SEPA:

O-SEPA is an excellent device to separate various kinds of cement, cement raw materials, limestone, quicklime, clay, slag, coke and other powdery materials.

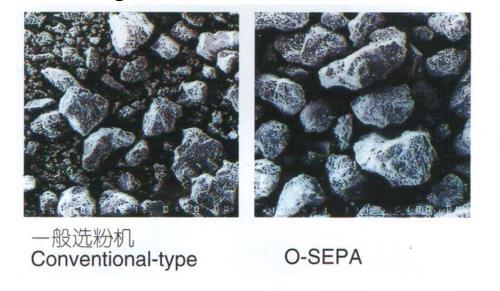

Condition of coarse powder in powder separator ( photo seen under electron microscope ) Circulating load 1.64 Circulating load 1.77

online message

Combined detachable three-cylinder dryer is mainly used for drying granular materials with certain humidity and granularity, such as yellow sand used in dry mortar industry, various specifications of sand used in foundry industry, blast furnace slag used in building materials and cement industry, small granularity of clay and fly ash, and small granular materials used in chemical industry which can not be chemically altered, and are not afraid of being soiled by high temperature and fumes