Product classification

Classification of heavy equipment

Reducer classification

Classification of heavy equipment

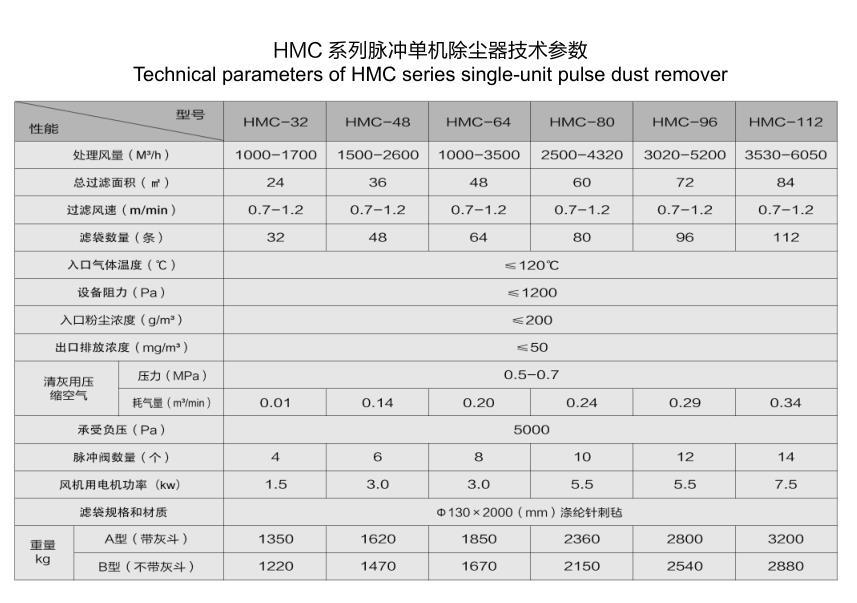

HMC series pulse single machine dust collector

Classification:

Powder Separation and Dust Removal Equipment

Key words:

Product Description

HMC series pulse single machine dust catcher is a new type of high efficient environmental protection equipment developed and designed by our factory on the basis of summarizing the advantages of similar products at home and abroad. The dust catcher adopts pulse blowing cleaning method, which has the advantages of good cleaning effect, high purification efficiency, large handling air volume, long service life of filter bag, small maintenance workload, safe and reliable operation. Widely used in building materials, machinery, metallurgy, mining, chemical and other industries, dust purification.

This series of dust catcher consists of shell, ash hopper, ash unloading device and ash cleaning system, etc. There are six specifications for this series of dust catcher, divided into A and B types, A type has standard ash hopper; B type has no ash hopper. When the dusty gas enters the dust collector, the coarse particles of dust fall into the dust hopper directly and play the role of pre-absorption, the dusty gas passes through the internal filter bag equipped with metal skeleton, the dust is arrested on the outer surface of the filter bag, and the purified gas passes through the clean room and is discharged by the fan, and the cleaning procedure of the dust collector is adjusted and determined by the controller according to the technological conditions. When the dust collector is working, with the accumulation of dust on the outer surface of the filter bag gradually increasing, the resistance of the dust collector is also increasing, when it reaches the set value, (the upper limit of the specified resistance or a certain time interval), the dust-cleaning controller sends out the dust-cleaning instruction, opens the pulse valve, and sprays the high-pressure gas of 0.5-0.7MPa in a very short period of time, which expands the filter bag, deforms and vibrates, and then removes the dust on the outer surface of the filter bag and falls into the dust hopper, and all the cleaning work is completed. The dust will be removed from the outer surface of the filter bag and fall into the dust hopper, then the dust cleaning work will be finished and the dust collector will return to normal operation.

online message

Combined detachable three-cylinder dryer is mainly used for drying granular materials with certain humidity and granularity, such as yellow sand used in dry mortar industry, various specifications of sand used in foundry industry, blast furnace slag used in building materials and cement industry, small granularity of clay and fly ash, and small granular materials used in chemical industry which can not be chemically altered, and are not afraid of being soiled by high temperature and fumes