Product classification

Classification of heavy equipment

Reducer classification

Classification of heavy equipment

Three-cylinder dryer

Classification:

Drying and Cooling Equipment

Key words:

Product Description

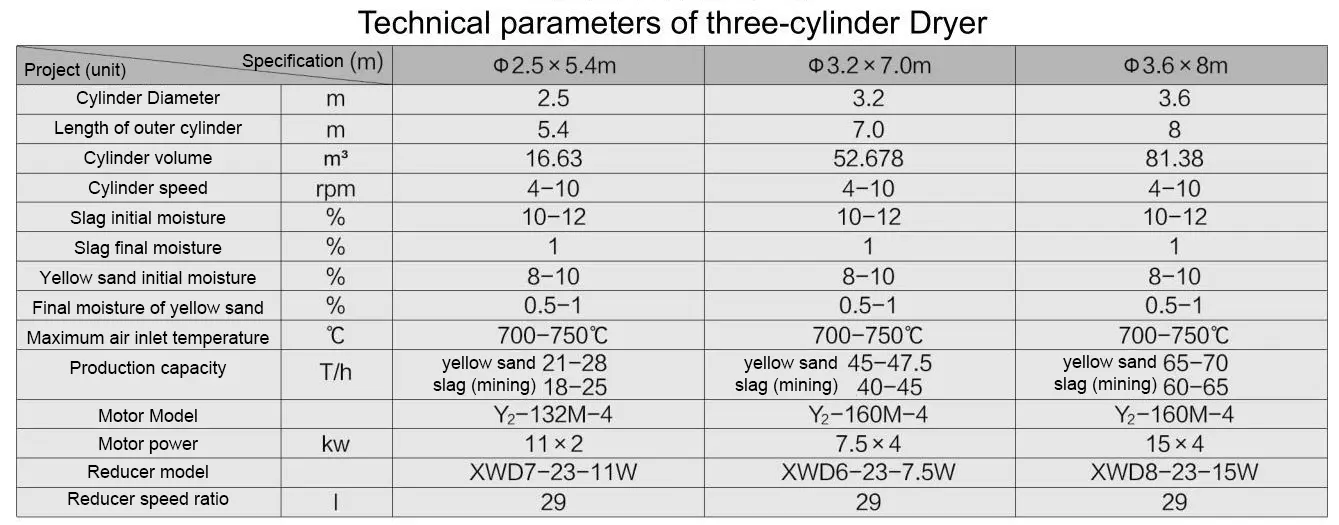

Combined detachable three-cylinder dryer is mainly used for drying granular materials with certain humidity and granularity, such as yellow sand used in dry mortar industry, various specifications of sand used in foundry industry, blast furnace slag used in building materials and cement industry, small granularity of clay and fly ash, and small granular materials used in chemical industry which can not be chemically altered, and are not afraid of being soiled by high temperature and fumes; Combined detachable three-cylinder dryer is different from traditional three-cylinder dryer, and it is the latest product developed by our company to completely solve the problem that the old three-cylinder dryer can not be overhauled and maintained, and it has a national patent. This is the latest product developed by our company to completely solve the problem that the old three-cylinder dryer can not be overhauled and maintained, and has obtained the national patent.

For the materials entering the dryer, it is required that the materials do not stick to the cylinder wall and the lifting board, and the initial moisture can be in the range of 10%-25%. Into the dryer heat exchange gas temperature should not be higher than 750 ℃, if there are special requirements for high-temperature drying, the dryer at the entrance to the cylinder and the lifting plate can be used for heat-resistant steel plate manufacturing; drying materials after the end of the moisture, according to the different industries on the requirements of the material, the moisture content can reach 1% -0.5% below.

online message

TVR/TVSU type raw material dynamic powder selector is suitable for roller press raw material final grinding system, mainly used with V type powder selector. The equipment is easy to operate, safe and reliable in operation, convenient in maintenance, with uniform and stable internal flow field, low pressure loss in the system, and good drying and grading effect.

O-SEPA high-performance powder separator is the fourth generation of high-efficiency powder separator utilizing the horizontal eddy current principle for classification, it is the powder classifying equipment which is improved and perfected by our company on the basis of introducing foreign technology and combining with the specific production practice of our country