Product classification

Classification of heavy equipment

Reducer classification

Classification of heavy equipment

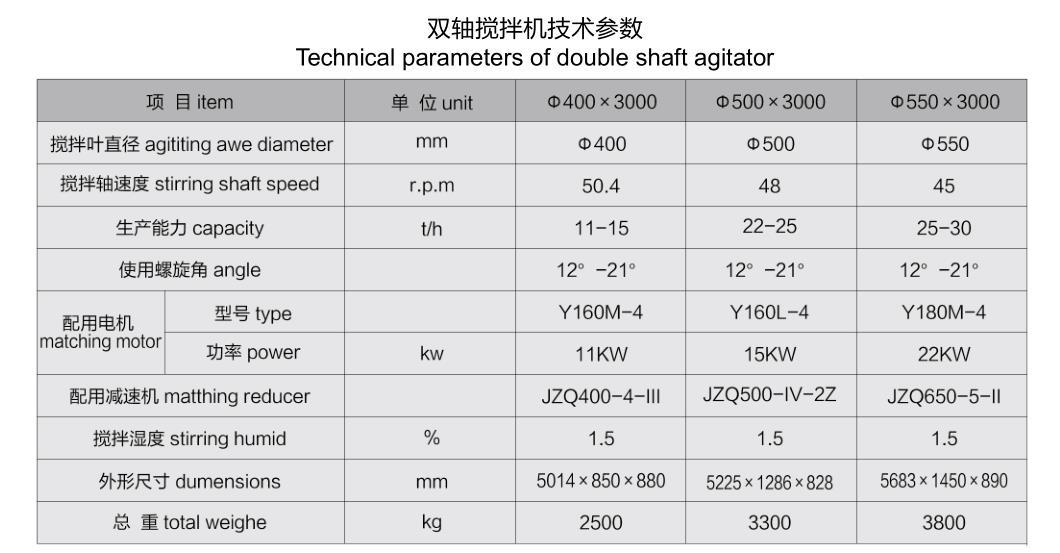

Twin shaft mixer

Classification:

Conveying Equipment

Key words:

Product Description

Double shaft mixer consists of mixing tank, mixing left and right shafts, mixing paddles, reducer, motor, and other parts. Using the synchronous rotation of two symmetrical spiral shafts, it can add water while conveying dry ash and other powdery materials, evenly humidify the dry ash powdery materials, so as to achieve the purpose that the humidified materials will not emit dry ash or ooze out water droplets, which is convenient for loading and transporting the humidified ash to trucks or transferring it to other conveying equipments.

online message

CZMG type series of high-efficiency ball mill is designed in the advantages and disadvantages of the open-flow grinding system, and has made significant improvements to the traditional ball mill. In addition to many advantages of the open-flow mill, compared with the same specifications of the ball mill

Through years of increasing cooperation with scientific research institutes, Long March Machinery Company has developed large-scale autogenous mills, semi-autogenous mills, overflow type mills, wind-swept coal mills which are widely used in metallurgy, mining, cement, electric power and other industries.